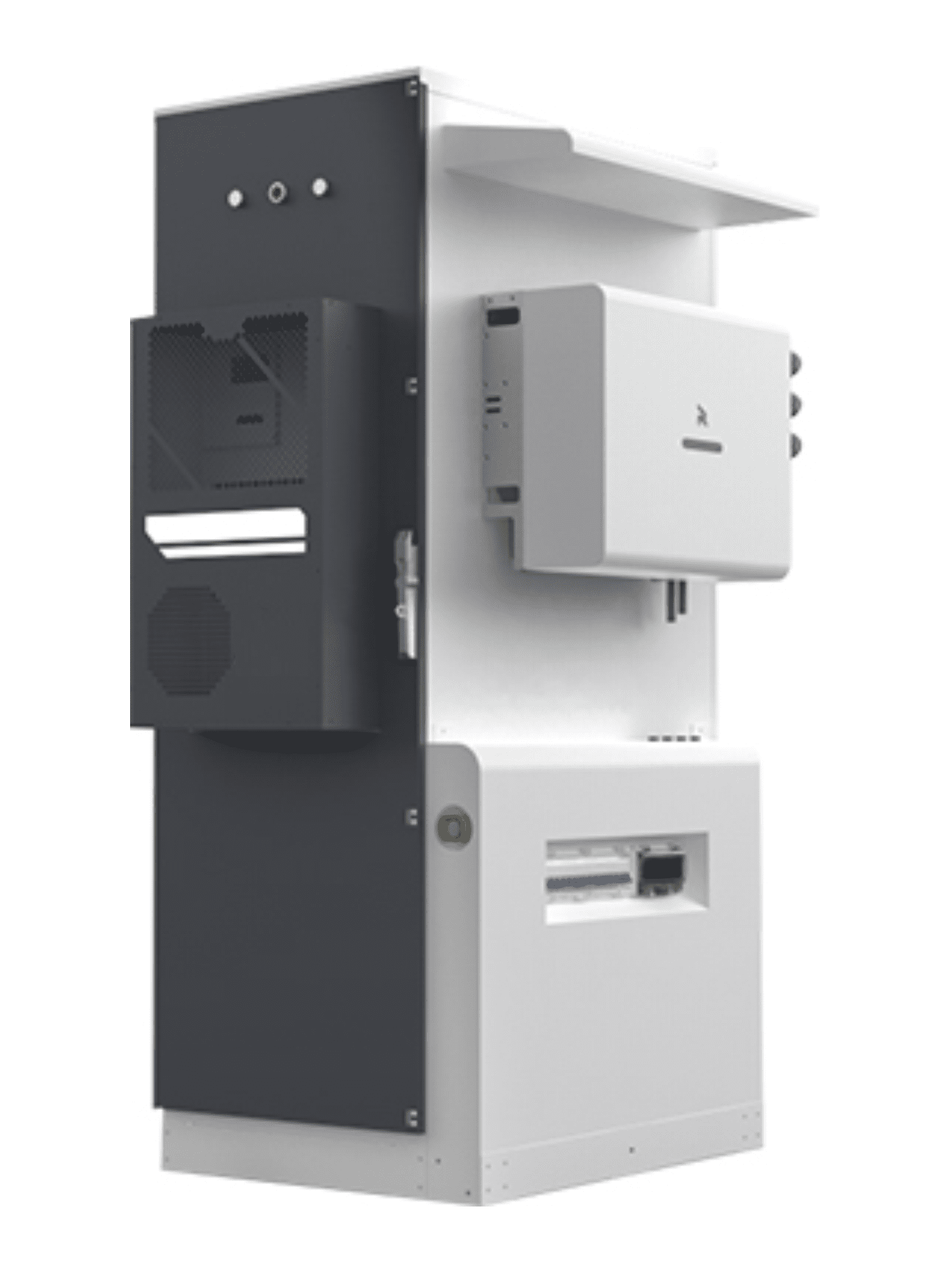

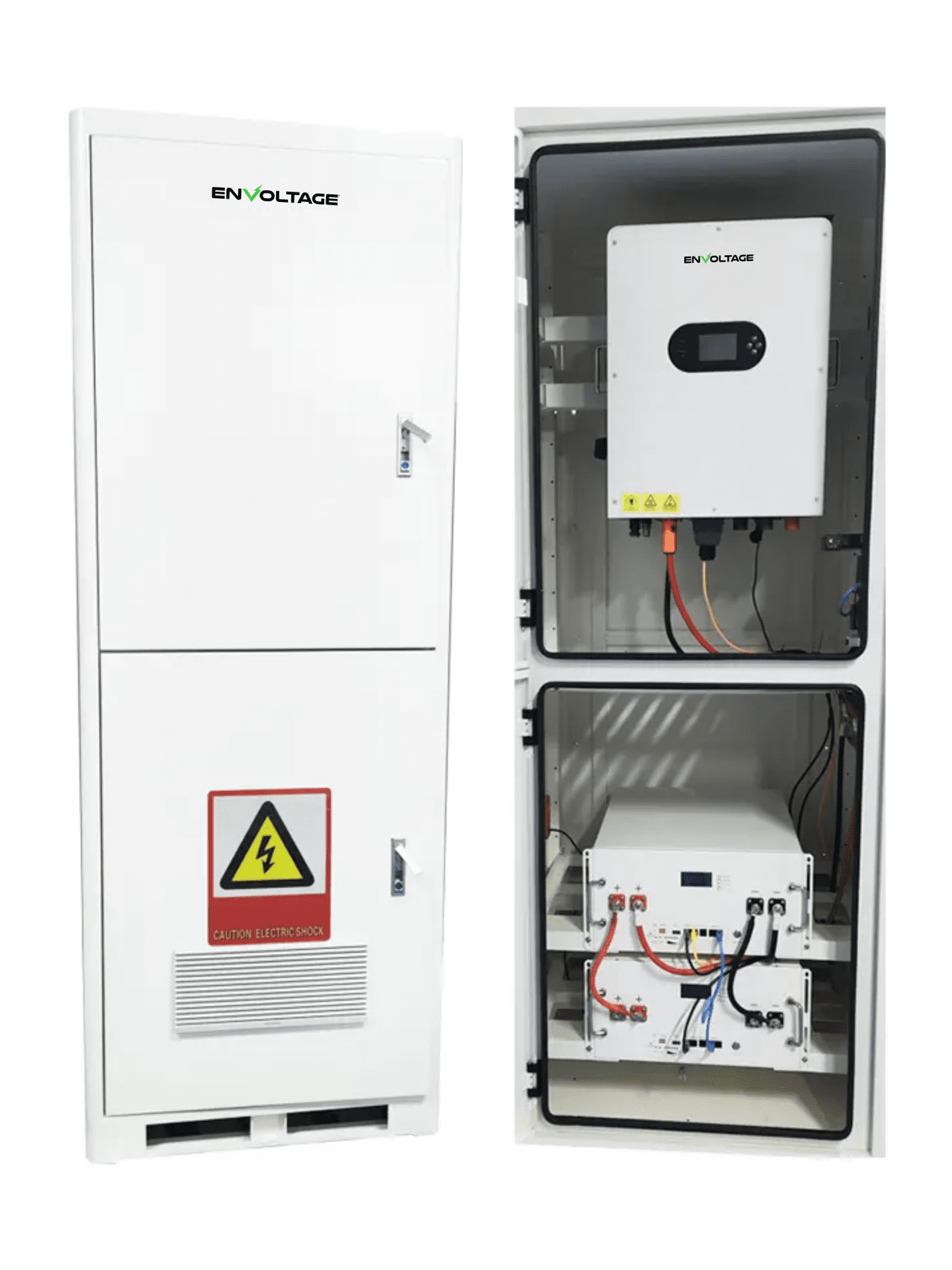

Commercial & industrial energy storage systems play a crucial role in enhancing energy efficiency and sustainability for businesses. By integrating EMS and BMS, Envoltage commercial energy storage systems achieve seamless coordination, cost savings, and improved energy management, contributing to greener operations and reduced utility expenses for businesses.

Learn More

Have questions or need help? Use this form to reach out and we will be in touch with you as quickly as possible.

Commercial and Industrial Energy Storage Systems Knowledge Base

Welcome to our knowledge base dedicated to Commercial and Industrial Energy Storage Systems (C&I ESS) — your comprehensive resource for understanding, selecting, and optimizing large-scale battery energy storage for business and grid applications.

Modern commercial and industrial facilities use battery-based energy storage to reduce electricity costs, increase energy resilience, and support renewable energy integration. These systems are the backbone of the future smart grid — combining high-performance batteries, advanced inverters, and intelligent energy management software.

What Are Commercial and Industrial Energy Storage Systems?

A Commercial and Industrial Energy Storage System (C&I ESS) is a high-capacity, battery-based solution that stores electricity for use during peak demand, outages, or renewable variability.

C&I ESS solutions typically connect to a facility’s main electrical service and integrate with solar arrays, EV chargers, or backup generators to deliver seamless power management.

These systems are deployed in:

- Manufacturing plants

- Warehouses and logistics centers

- Office and retail complexes

- Data centers

- Utilities and microgrids

Key Benefits for Businesses

1. Peak Demand Reduction

Store energy during off-peak hours and discharge it during high-rate periods to lower utility bills.

2. Energy Resilience and Backup Power

Maintain operations during grid outages with instant battery backup and seamless transition control.

3. Renewable Energy Optimization

Pair with solar or wind to store excess generation and increase self-consumption efficiency.

4. Power Quality and Load Management

Reduce voltage fluctuations, improve power factor, and stabilize sensitive equipment performance.

5. Sustainability and Carbon Reduction

Lower emissions by reducing reliance on diesel generators and maximizing renewable usage.

System Components and Architecture

Battery Modules

High-energy lithium-ion (LFP/NMC) or flow batteries designed for long cycle life and industrial duty.

Power Conversion System (PCS)

Bi-directional inverters that manage AC/DC conversion, grid interaction, and islanding operation.

Energy Management System (EMS)

Centralized software that controls charge/discharge cycles, monitors grid conditions, and provides analytics for cost optimization.

Thermal and Fire Management

Ensures battery safety and longevity through intelligent cooling and integrated fire suppression systems.

Switchgear and Integration Controls

Custom electrical interface components for safe grid connection and load transfer.

Applications and Use Cases

- Peak shaving: Reduce utility demand charges and optimize time-of-use billing.

- Backup power: Maintain business continuity during blackouts.

- Microgrids: Combine solar, wind, and storage for self-sufficient energy operations.

- EV fleet charging: Support high-demand charging without exceeding grid capacity.

- Power export and grid services: Participate in demand response or frequency regulation programs.

Sizing and Design Considerations

- Energy Capacity (kWh / MWh): Determines how long stored power can sustain loads.

- Power Output (kW): Defines the rate at which the system can discharge energy.

- Cycle Life: Measured in charge/discharge cycles, typically 5,000–10,000 for C&I systems.

- Depth of Discharge (DoD): Impacts usable energy and battery lifespan.

- Installation Environment: Indoor vs. outdoor, containerized vs. modular systems.

Professional site assessment and load analysis are essential to ensure optimal design and ROI.

Safety and Compliance Standards

Commercial energy storage systems must meet strict safety and performance standards, including:

- UL 9540 / UL 9540A: System-level safety certification and thermal runaway testing.

- NFPA 855: Installation standard for stationary energy storage systems.

- IEEE 1547: Interconnection standard for distributed energy resources.

- Local AHJ and utility interconnection approvals.

Proper ventilation, monitoring, and maintenance are critical for long-term safety.

Monitoring, Maintenance, and Lifecycle Management

Modern C&I ESS solutions use remote monitoring platforms and AI-driven analytics to optimize performance and detect issues early.

Routine maintenance includes:

- Visual and electrical inspections

- Battery health diagnostics

- Firmware updates and EMS tuning

- Fire suppression and HVAC system checks

Lifecycle management includes battery recycling or repurposing at end-of-life to ensure sustainability.

Financial and Operational Advantages

- Demand charge reduction: Immediate utility savings of 20–40%.

- Incentives and tax credits: Eligible for federal and state programs (including ITC for storage).

- Improved facility uptime: Critical for manufacturing, cold storage, and healthcare.

- Revenue opportunities: Participate in grid balancing or ancillary service markets.

The typical ROI for well-designed C&I ESS systems ranges from 3–7 years, depending on location, usage profile, and incentive structures.

Frequently Asked Questions

What’s the difference between commercial and residential energy storage?

Commercial systems are larger, higher-voltage installations built for peak management and continuous operation, often integrated with on-site renewables or EV charging.

Can energy storage operate off-grid?

Yes. When combined with solar and intelligent controls, C&I systems can support off-grid or islanded microgrids.

What’s the average lifespan of a commercial battery system?

10–15 years, depending on chemistry, duty cycle, and maintenance practices.